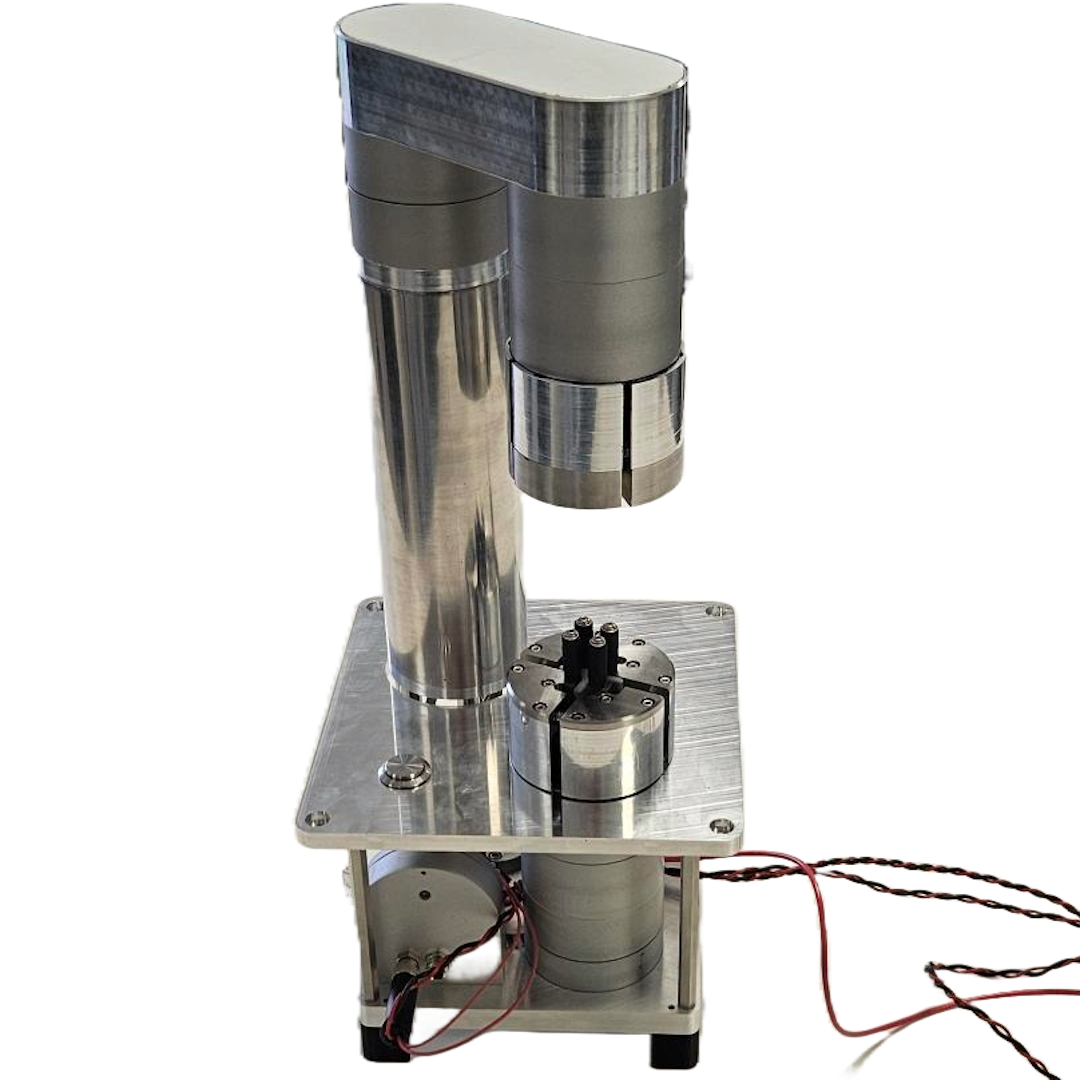

MiniCapper

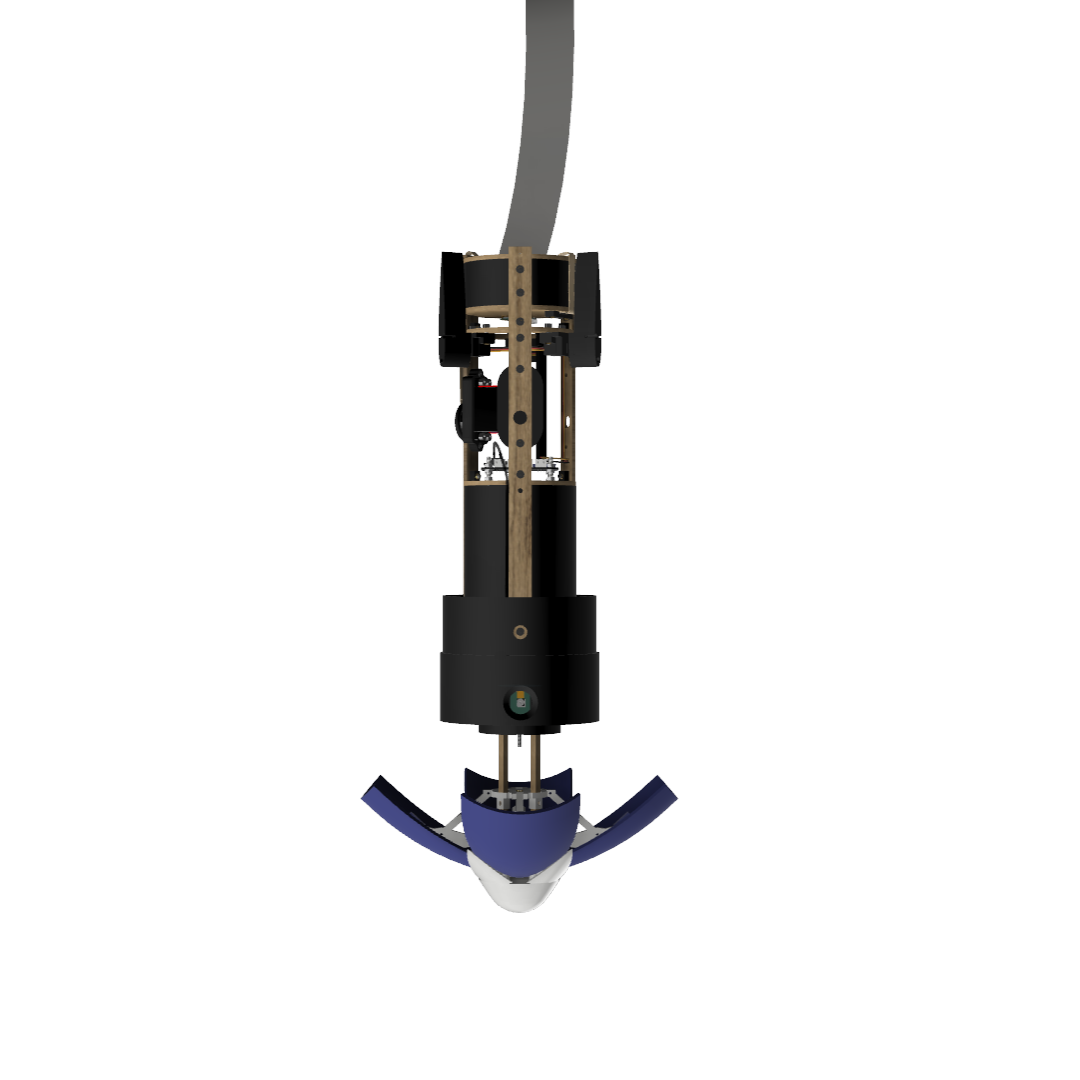

The MiniCapper is a standalone device to cap and decap vials for use in laboratory automation.

The project was progressed from initial concept through to a final version, tested in a laboratory

environment.

The system was designed for manufacturability and ease of assembly, with all custom components manufactured

from machined metal.

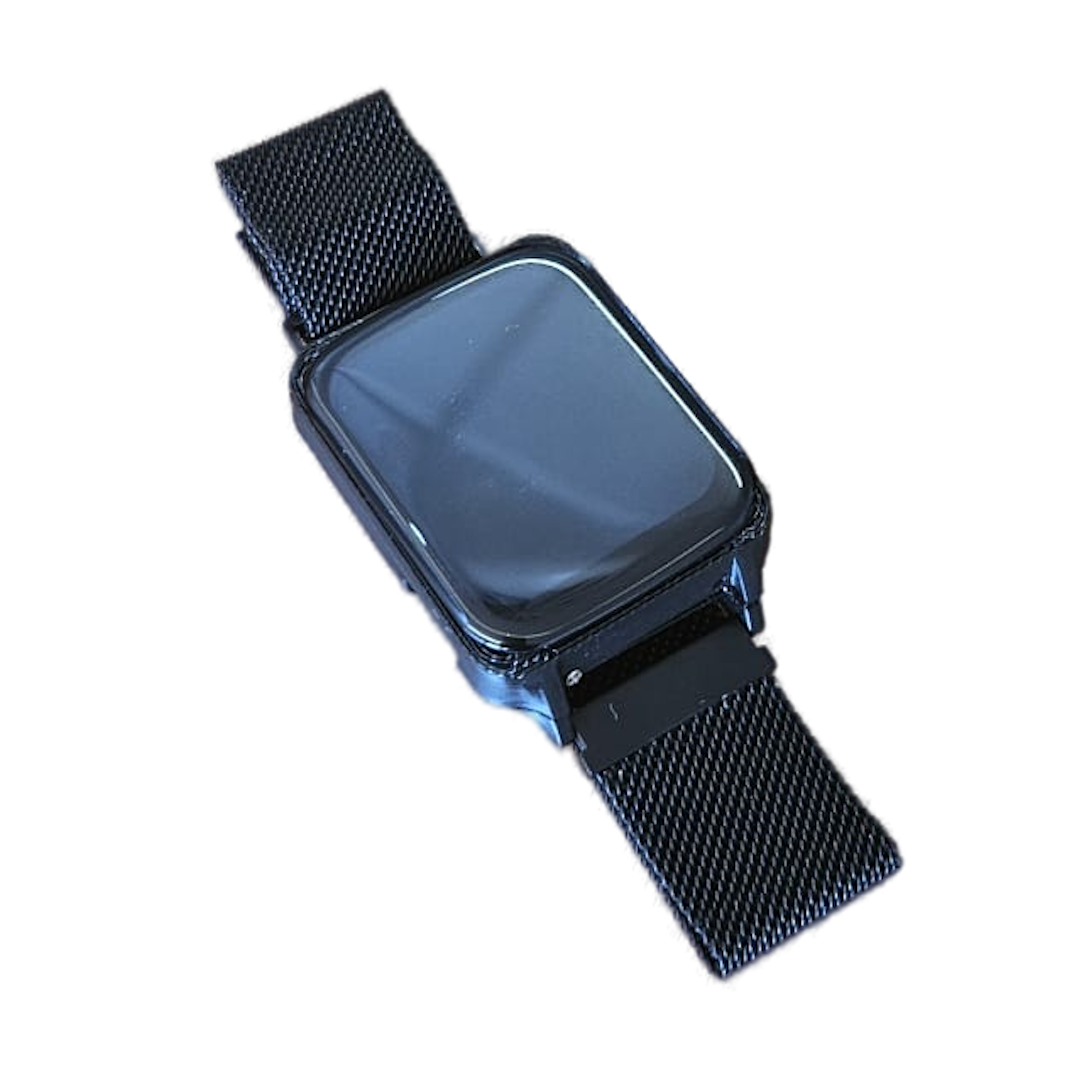

EWatch

The EWatch is a programmable smartwatch intended for hobbyists and developers.

The project is currently in development, with availability for pre-order.

This project predominantly involved electronics design, with a strong emphasis on low power consumption and

miniaturisation.

Mechanical considerations include ergonomics, aesthetics, and machinability.

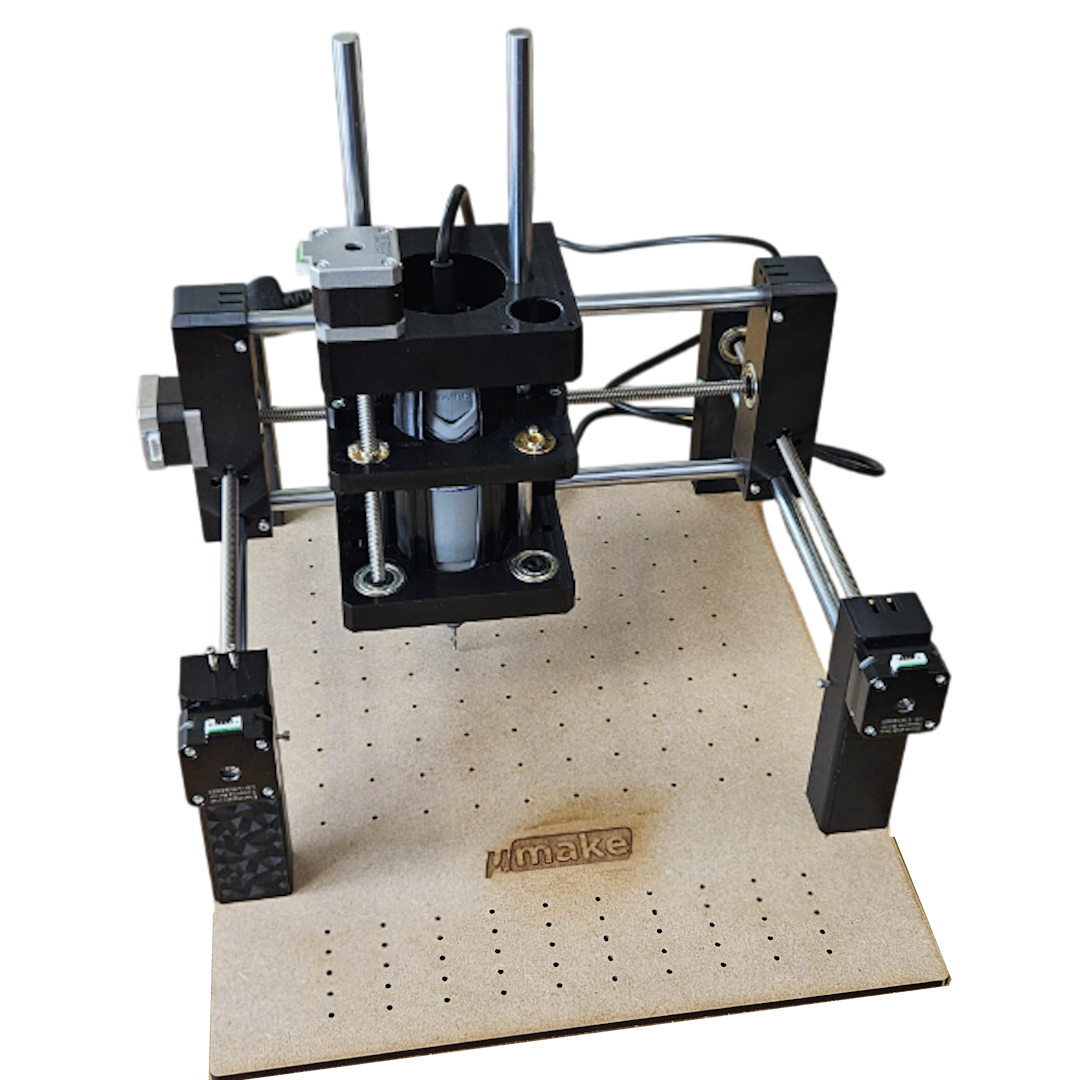

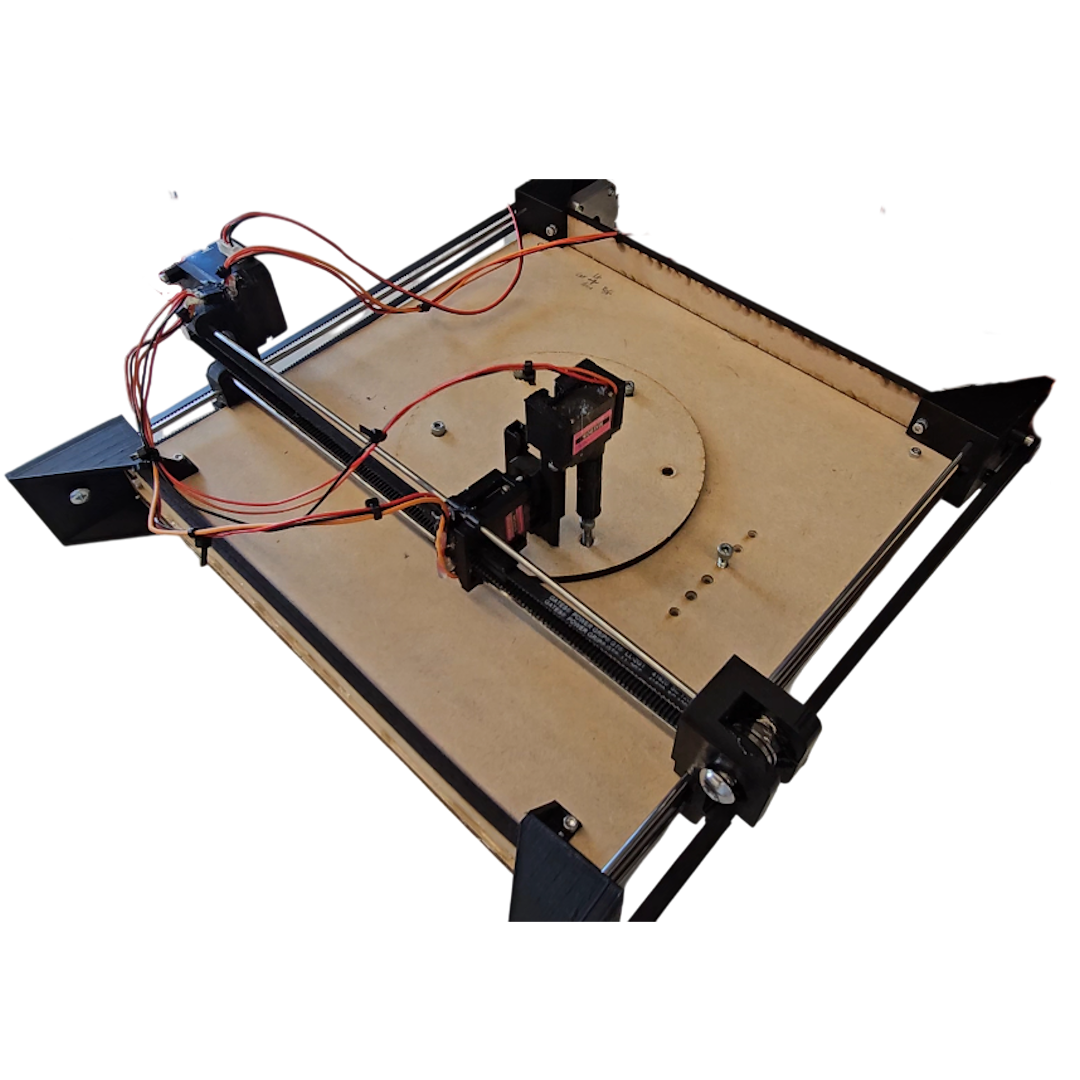

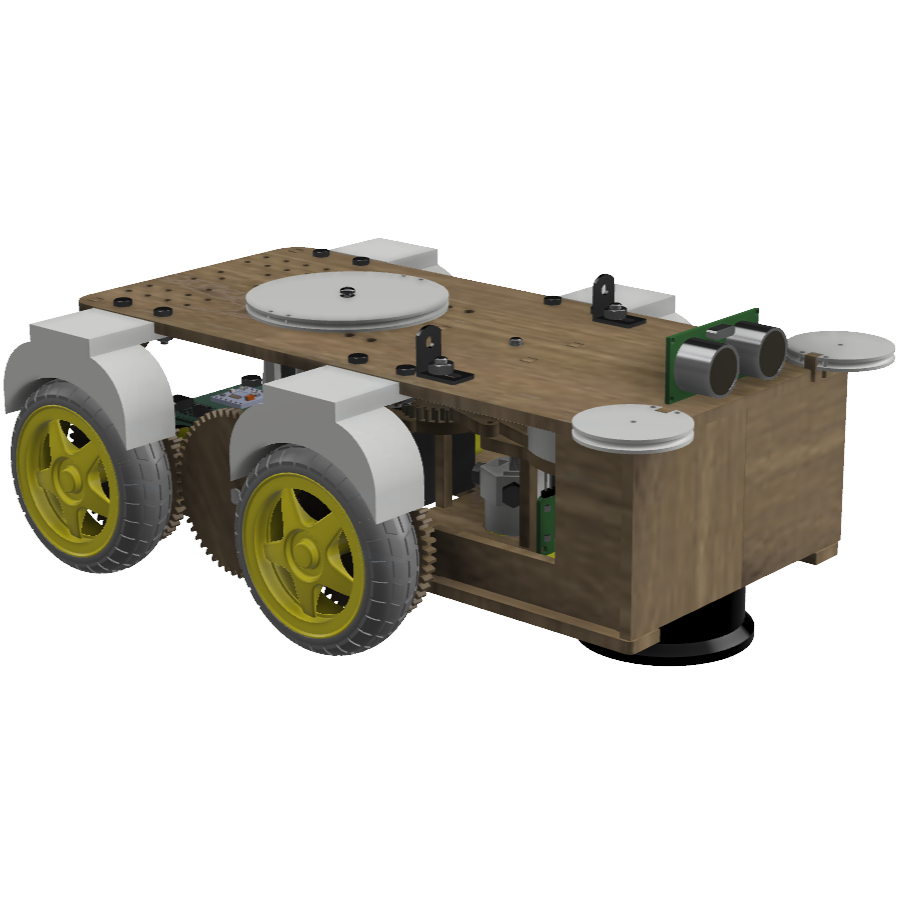

EWrapper

The EWrapper is a device designed to autonomously wrap combat

sports hand wraps.

The project originated from a clearly identified pain point and was progressed to market on a small

scale.

The design is optimised for speed and ergonomics; aesthetics and manufacturability were not primary

considerations, as the product was produced via small-scale 3D printing.

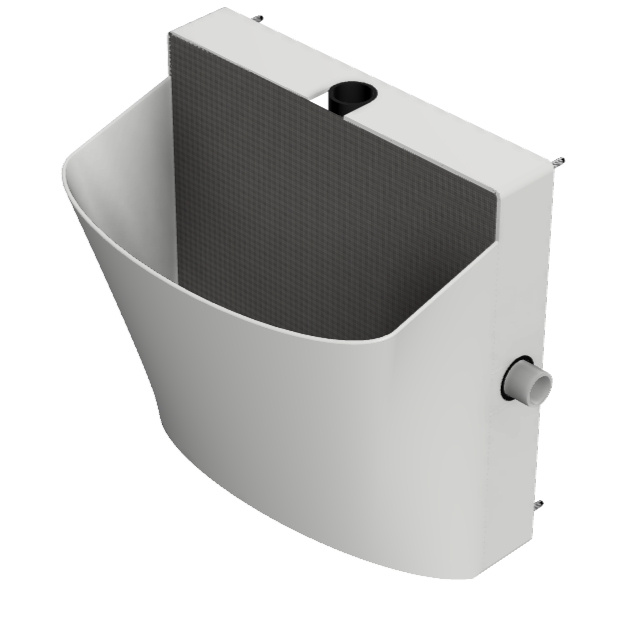

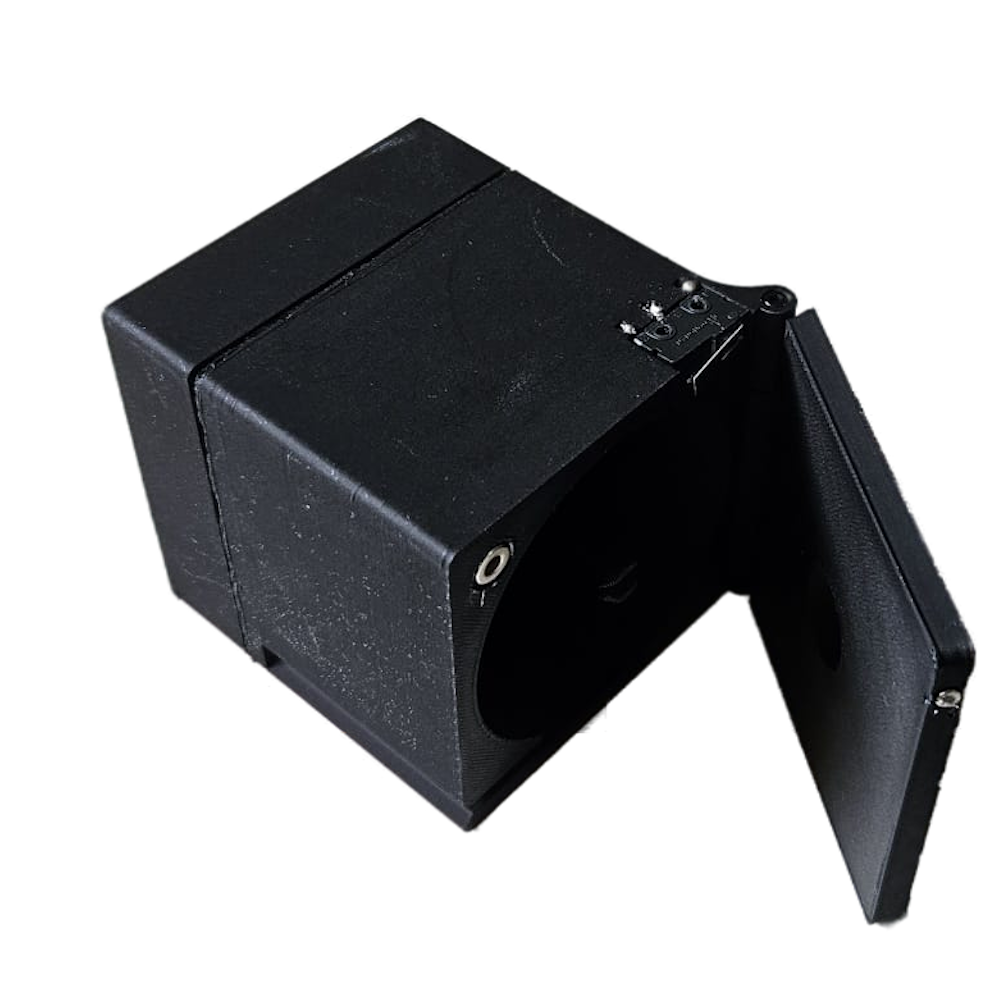

Custom Mouthguard Case

Custom mouthguard cases allow clear distinction

between

otherwise indistinguishable products.

The project was started with a pain point and progressed to market.